How Do Electric Winches Work: Understanding Motor Power Dynamics

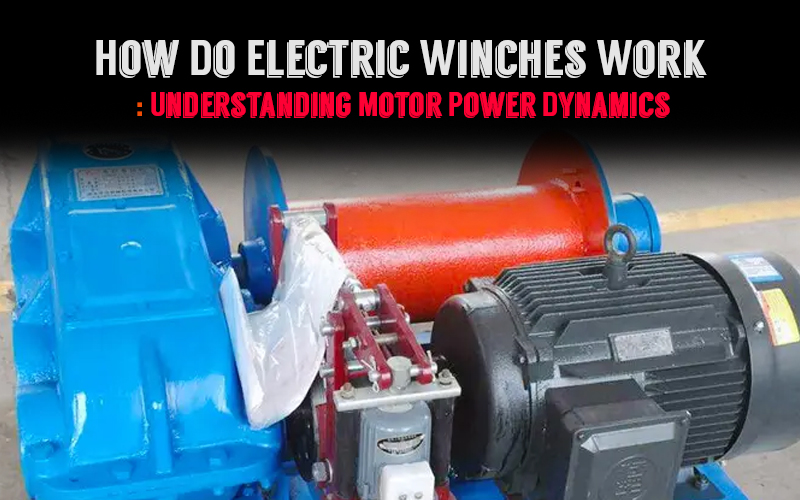

Electric winches operate by converting electrical energy into mechanical force, utilizing a motor to wind a cable or rope around a drum. They provide controlled pulling power for lifting or towing applications.

Electric winches have become a crucial tool in various industries, from off-road recovery to construction and marine applications. These devices offer a reliable and efficient way to move heavy loads with precision and ease. Comprising an electric motor, gear train, winch drum, and cable or rope, electric winches harness the power supplied by a battery or direct power source to initiate the winding process.

Motor turns the drum, coiling the cable around it, either pulling a load towards the winch or lowering it with command. Often equipped with a remote control, these winches allow for safe operation from a distance, ensuring operators manage the tasks without direct interaction with the load, providing an added layer of safety in potentially hazardous environments. With simple installation and minimal maintenance, electric winches are a go-to solution for many who require powerful and dependable pulling assistance.

Basic Components Of An Electric Winch

Understanding how an electric winch operates starts with its basic components. Each part works together to create a powerful tool for pulling or lifting. Let’s explore these essential pieces.

Motor

The motor is the powerhouse of the winch. It converts electrical energy into mechanical power. This power then turns the winch drum to wind or unwind the cable. Electric winch motors come in different sizes. The size you need depends on the weight you plan to pull.

Gearbox

Attached to the motor, you’ll find the gearbox. It boosts the motor’s torque. This means the winch can pull heavier items with less strain on the motor. Gear ratios vary. A higher gear ratio provides more pulling power. Meanwhile, a lower ratio offers faster cable retrieval.

Drum

The drum is the part where the cable wraps around. When the motor activates, the drum starts spinning. This rolling action either pulls the cable in or lets it out. The drum’s size affects how much cable it can hold and how fast it can operate.

Control System

This is the user’s interface with the winch. The control system can be a remote or a direct switch. It lets the operator start and stop the winch. It also controls the direction in which the cable moves. Safety features are often included to prevent accidents.

Understanding The Functioning Of Electric Winches

Electric winches simplify lifting and moving heavy loads. But, how do these work? Let’s delve deeper and shed light on the functioning of electric winches.

Power Source

Power source plays a pivotal role. Most electric winches work on electricity. This power comes from a vehicle battery or a standalone power unit.

Motor And Gearbox Operation

A motor and gearbox combo is the muscle behind the winch. These convert electric energy into mechanical energy. The gearbox reduces the speed while increasing the force.

Engaging The Drum

| Step | Action |

|---|---|

| Step 1 | The gearbox moves the drum. |

| Step 2 | The drum winds or unwinds the wire rope. |

| Step 3 | The wire rope does the heavy-duty work. |

Control System Operation

- The control system is the brain of the winch.

- This system interfaces with the motor and the brake.

- The control system oversees the smooth operation of the winch.

Applications And Benefits Of Electric Winches

Electric winches prove to be game-changers in various sectors. Their operational ease, versatility, and efficiency make them a prime choice for many industries.

Off-road Vehicles

Electric winches are popular equipment in the off-road vehicle industry. They help enhance the functionality of these vehicles in remote areas. Let’s delve into the characteristics that make them desirable for off-road vehicle users:

- Assist in pulling vehicles out from mud, sand, or rock terrains.

- Can handle heavy weights effortlessly.

- Ensure the safety of travelers in adverse conditions.

Marine Industry

Marine industry also finds immense use of electric winches. Some notable applications and advantages include:

- Helps in docking, anchoring, and positioning of boats and ships.

- Serves a crucial role in rescue operations at sea.

- Offers a hands-free operation, improving safety measures.

Construction And Manufacturing

Construction and manufacturing sector cherish the benefits that electric winches bring forth. Some of the key utilities and profits are:

- Aid in lifting and moving heavy equipment and materials.

- Fosters a safe working environment by reducing manual labor risks.

- Contributes to increased productivity and efficiency.

Importance Of Electric Winches

Electric winches are an essential workhorse in varied fields, arising from their array of benefits:

- Improved Safety: Reducing human efforts, electric winches increase safety at work.

- Flexibility: They are adaptable to different operational needs.

- Efficiency: Electric winches can handle heavy weights with less power, promoting energy efficiency.

- Easy Operation: They streamline tasks with their push-button controls.

Maintenance And Safety Considerations

Maintenance and Safety Considerations play a crucial role in the longevity and proper functioning of electric winches. Regular care ensures they perform seamlessly when needed. It also helps to prevent accidents that could lead to serious injuries or damage to property. Let’s delve into some essential practices to keep these powerful machines in tip-top condition.

Regular Inspection And Lubrication

Like any mechanical device, electric winches require consistent checks to stay operational. Assess all components to catch any wear or damage early.

- Inspect cable integrity: Look for frays or kinks.

- Check electrical connections: Ensure tight, corrosion-free contacts.

- Validate the winch structure: Monitor for cracks or bends.

Lubrication is also key. Apply recommended grease to gears and bearings. This reduces friction and wards off rust.

Proper Loading And Operation

Overloading a winch can lead to failure. Always refer to the manufacturer’s guidelines. Use caution when loading and operating the winch to ensure safety:

- Stick to the weight limits: They’re set for a reason.

- Operate smoothly: Abrupt movements can strain the winch.

- Maintain clearances: Keep the area around the winch free of obstructions.

Electrical And Fire Safety

Electric winches pose electrical and fire risks if mishandled. Implement the following practices:

- Use proper fuses and breakers: Match the winch’s electrical demands.

- Regularly inspect wiring: Replace if insulation is damaged.

- Keep a fire extinguisher handy: Be prepared for electrical fires.

Choosing The Right Winch For The Job

Selecting the suitable winch is the first step to ensure safety and efficiency. Consider the following factors:

| Factor | Detail |

|---|---|

| Load Capacity | Must exceed what you plan to lift or pull. |

| Duty Cycle | Choose a winch that can handle the operation frequency. |

| Environment | Ensure the winch is suitable for the working conditions. |

Frequently Asked Questions On How Do Electric Winches Work

Are Electric Winches Better Than Hydraulic?

Electric winches offer ease of use and are excellent for short, intermittent tasks. Hydraulic winches excel in continuous operation and heavy-duty applications, depending on power availability and usage frequency. Both types have specific advantages based on the application context.

How Are Truck Winches Powered?

Truck winches derive power mainly from two sources: Vehicle’s battery, which powers electric winches; and the truck’s engine, driving hydraulic winches. Both types provide substantial pull strength.

Why Are Winches So Powerful?

Winches are powerful due to their robust gear systems. These gears multiply force, enabling the winch to pull heavy loads. High-quality materials and design also enhance their strength.

What Is The Difference Between Electric And Mechanical Winches?

Electric winches use motor power to pull loads, offering ease of operation and consistent strength. Mechanical winches require manual operation, using physical force and gears for movement, providing reliability without the need for a power source.

Conclusion

Understanding how electric winches work is crucial for beneficial use, especially in heavy-duty work scenarios. Their robust technology and great utility facilitate outstanding load-bearing tasks. By grasping the intricacies of their operation, you increase safety levels and improve efficiency. Therefore, let the power of electric winches be your workhorse, simplifying tasks and saving time.